Vaccuum Casting

We have the leading vacuum remolding technology to quickly replicate polyurethane cast parts similar to engineering plastics through silicone molds, which is ideal for functional testing and small batch production of prototypes.

What is vacuum remolding?

Vacuum re-molding, also known as silicone re-molding or hand-plate re-molding, is a cost-effective method of producing small quantities of plastic parts.

Vacuum remolding is mainly used in ?

Vacuum re-molding can use a variety of polyurethane resin materials to simulate different engineering plastics, such as ABS, PC, PP, etc., to produce parts with different properties to meet the needs of special application scenarios.

Due to the flexible material selection and lower cost of vacuum re-molding, it is suitable for manufacturing medical devices, personalized consumer products, customized housings and other small-lot or customized products.

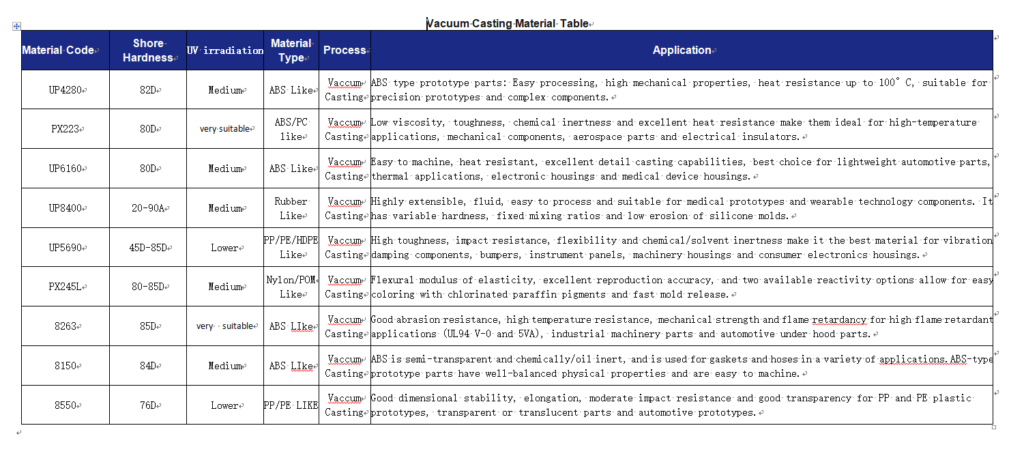

Materials for vacuum remolding

Vacuum replica mold technology

- Reproduction accuracy: standard tolerance is ±0.15mm/100mm, up to ±0.05mm.

- Maximum mold size: Vacuum casting equipment supports a maximum mold size of 2.0m x 1.2m x 1.0m.

- Minimum Wall Thickness: The minimum wall thickness of the part is 0.5mm, and the best range is 1.5mm to 2.5mm.

- Mould life: each silicone mould can replicate up to 20 pieces, but for parts with high quality requirements , the mould can usually only produce 10 to 12 castings.

- Delivery time: Typically, up to 50 prototypes can be made within 10 to 15 days, depending on part size and volume.

- Surface treatments: color addition, frosted etching, clear polishing, painting, plating, metal inserts and overmolding are available.

Applications of vacuum remolding

suitable for customized small batch parts without investment in injection molds.

Cost-effective silicone molds facilitate engineering verification and design adjustments.

various colors, textures and surface treatments are available to help select the best design solution.

Small batch re-molded parts are suitable for displaying to potential customers for trade shows and promotional materials.