Rapid Tooling

Small batch injection molding using rapid tooling provides fast, low-cost access to high-quality injection molded parts with production-grade materials and processes.

What is Rapid Tooling ?

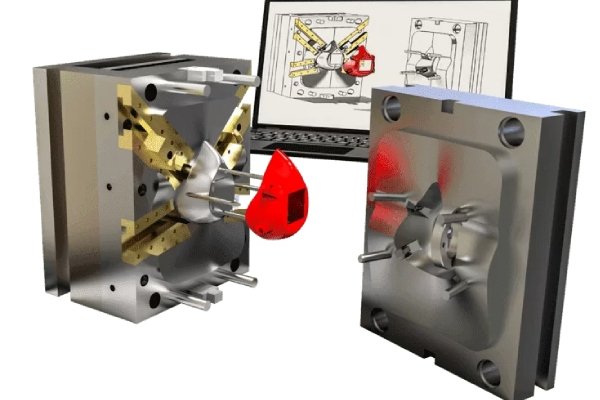

Rapid Tooling (Rapid Tooling), also known as Quick Tooling, refers to the molds manufactured in a relatively short period of time by means of rapid prototyping technology, computer-aided design (CAD), computer-aided manufacturing (CAM), etc. Rapid Tooling is a tooling process that is more simplified than traditional tooling and can significantly reduce the development cycle of small series production or trial production of new products.

Where are rapid tooling applications?

When product demand is low or the market is uncertain, rapid tooling can meet small-batch production needs while reducing mold-making costs.

During the development of new products, rapid tooling allows for quick production of sample parts for functional validation and market testing.

Rapid tooling significantly shortens mold development time by minimizing manufacturing steps and utilizing rapid prototyping technologies.

Why choose our rapid mold manufacturing?

Rapid tooling is produced quickly, making it ideal for small-batch production with strict lead time requirements.

Compared to traditional molds, rapid tooling is more cost-effective due to a simplified manufacturing process that requires less time and labor.

Parts produced with rapid tooling may have lower durability and a shorter lifespan, but the acceptance of lower quality can potentially increase profitability.

Rapid Tooling Types

Quick tooling types can be made of aluminum or steel, with P20 being the commonly used steel.

Fast processing and cheap material, but thermal and cooling properties are not as good as steel, and many customers do not choose it because of the quality of the parts.

P20 is cost-effective and will not rust over a well-maintained life cycle.

Why Choose Us

Our Advantages in Rapid Tooling Manufacturing

Experienced in CNC machining, EDM machining and surface treatment, specializing in rapid tooling and small batch injection molding.

Experienced in CNC machining, EDM machining and surface treatment, specializing in rapid tooling and small batch injection molding.

.Help you speed up pre-production testing and validation, shorten the production gap, and perfect your design for quicker time-to-market.