Service

Funprototype gives you the best service!

What we offer

What are our services?

Customize the optimal CNC machining solution for your plastic and metal parts to achieve on-demand production and precise delivery, allowing you to make a quantum leap forward.

Small batch injection molding using Rapid Tooling provides fast, low-cost access to high-quality injection molded parts using production-grade materials and processes.

Provide professional rapid prototyping 3D printing services, SLA, SLS 3D printing template precision and durability, unlimited presentation of your perfect design!

With the leading vacuum remolding technology, the polyurethane casting of plastic is quickly reproduced through silicone molds, the best choice for small batch production.

CNC Plate Processing

We excel in CNC precision machining, particularly in creating functional prototypes with complex geometries, offering unparalleled support for your design validation and engineering tests. Whether it’s finely detailed optical parts or intricately structured aluminum enclosures, we deliver perfection every time.

CNC machining enables extremely high dimensional accuracy, ensuring that parts conform to design requirements.

CNC machining can handle a wide range of materials, including metal, plastic, wood, etc., with great flexibility.

CNCs are capable of machining complex geometries for functional prototypes and final products.

mold manufacturing

Rapid tooling is produced quickly, making it ideal for small-batch production with strict lead time requirements.

Compared to traditional molds, rapid tooling is more cost-effective due to a simplified manufacturing process that requires less time and labor.

Parts produced with rapid tooling may have lower durability and a shorter lifespan, but the acceptance of lower quality can potentially increase profitability.

3D printed

3D printed handbags are used to test the functionality, strength and assembly of a product to ensure that the various components can fit together accurately, thus reducing problems in the subsequent manufacturing process.

Before manufacturing the mold, 3D printing hand panel can be used to verify the feasibility of the mold design and the manufacturing process of the product, reducing the risk and cost of mold modification.

In the new product development stage, 3D printing templates can quickly generate physical models to help you verify the functionality, appearance and structure of your design, and identify and correct design defects in a timely manner.

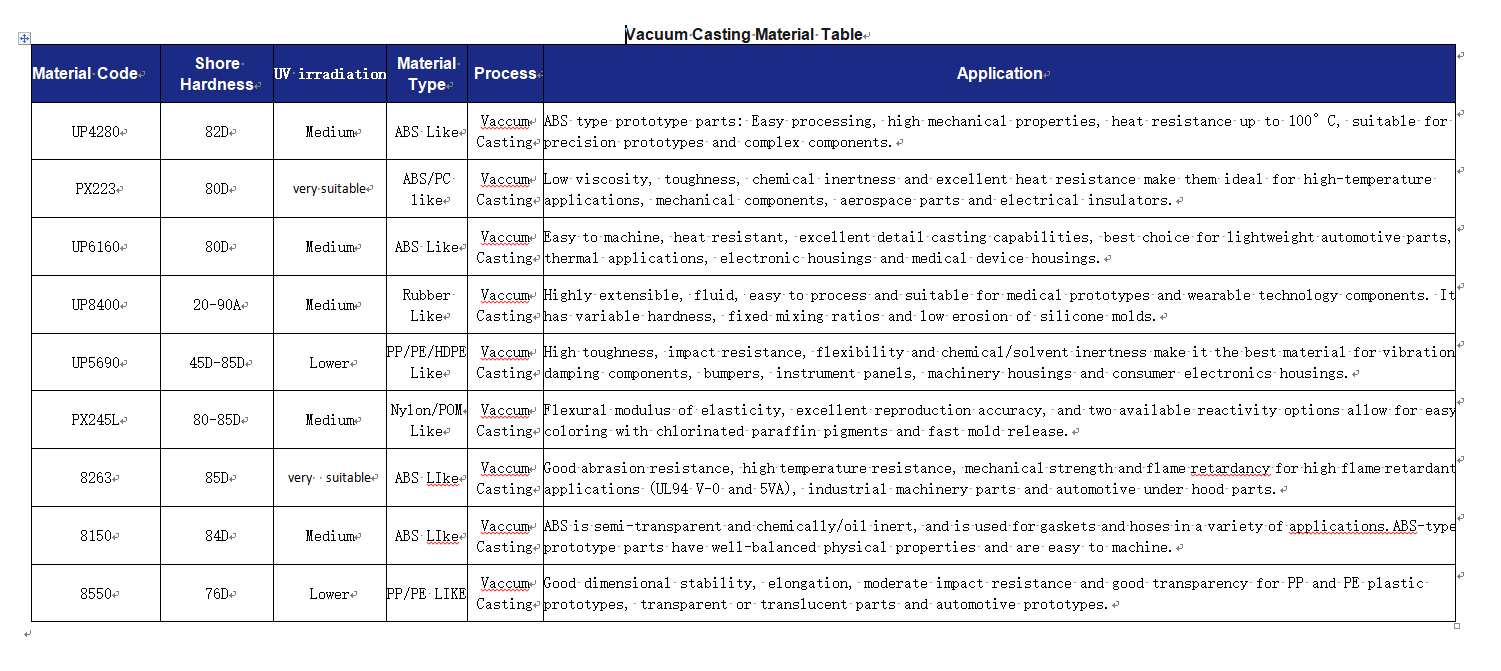

Vaccuum Casting

suitable for customized small batch parts without investment in injection molds.

Cost-effective silicone molds facilitate engineering verification and design adjustments.

various colors, textures and surface treatments are available to help select the best design solution.