"We take responsibility for your products as if they were our own."

“Rapid prototyping and small-batch manufacturing have distinct characteristics.”

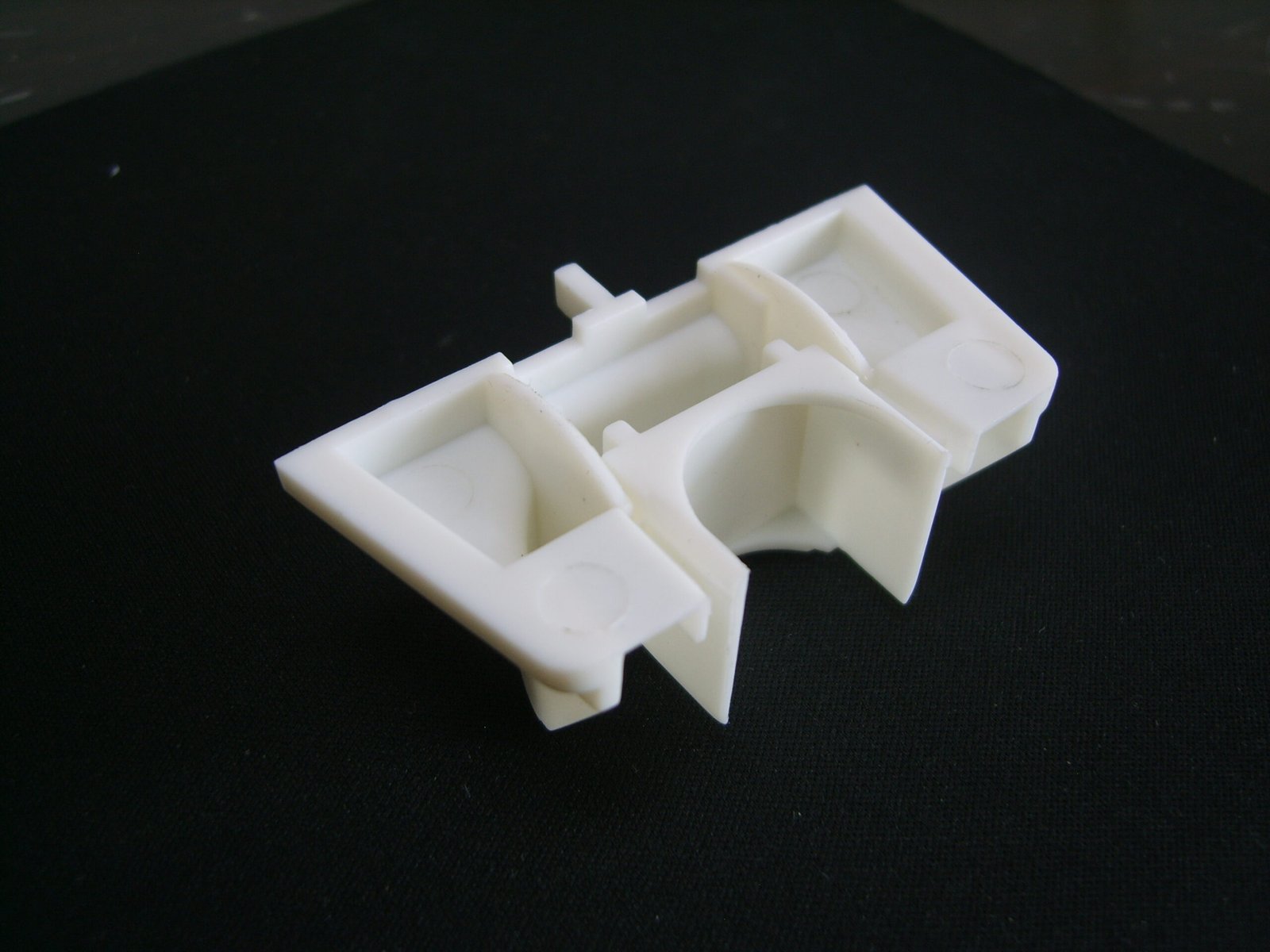

quickly transforming design concepts into physical models

Compared to traditional mold making and large-scale production, rapid prototyping has relatively lower early-stage costs.

‘Meet customers' personalized needs by producing unique products.

What we offer

Benefits of rapid prototyping

When there is a short-term high demand for certain products, small-lot manufacturing can quickly replenish inventory and avoid lost sales due to out-of-stocks.

Shortens the time from design to market, reducing R&D costs and time-to-market costs. It enables you to enter the market faster and occupy the first opportunity to improve competitiveness.

You can flexibly adjust subsequent production quantities and specifications in response to changes in the market or changes in your own needs.

For newly launched products or products with uncertain market response, small lot manufacturing facilitates market testing and reduces market risk.

Reduce losses by identifying design flaws and problems early in product development and avoiding discovery during mass production

Ultra-fast production

Our production process

Upload your documents and project information via the inquiry page, all data is protected by a Non-Disclosure Agreement (NDA).

Within 12 hours, we will provide a DFM (Design for Manufacturability) analysis report and a competitive quote.

After order confirmation, we will start the manufacturing process based on your documented data.

The board or part will be manufactured within a few days and delivered directly to you via courier.

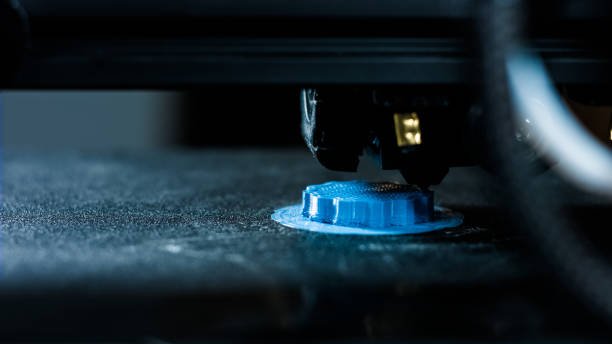

Customized Additive Manufacturing Services

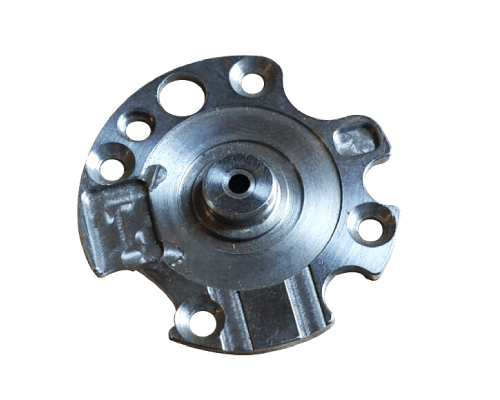

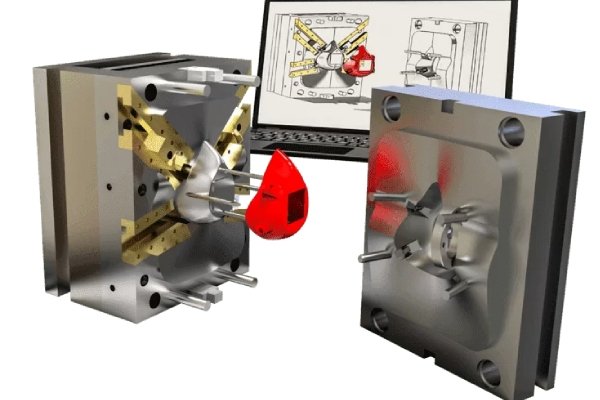

CNC hand plate processing, 3D printing, vacuum re-molding, rapid tooling manufacturing, sheet metal hand plate making, hand plate post-processing.

Provide customized parts processing and manufacturing, including CNC machining, injection molding, die-casting molding, sheet metal processing, surface treatment

TEstimonial

What they say about us

Rapid prototyping and hand-boarding technology help companies to develop new products, get physical models, check the design effect, change potential problems. Small batch manufacturing is good for market testing and risk reduction. High efficiency and cost control, as a powerful assistant for innovation.

Jakarta

Satisfied with the cooperation with hand board and rapid prototyping, small batch manufacturing. The team is professional, the hand plate and small batch product quality is high, help to promote new products, seize the market opportunity, highly recommended.

Medan

Hand-boarding and rapid prototyping, small batch manufacturing to help creative realization, low-cost test market, get customer feedback, increase competitive opportunities. Thank you for your service and we look forward to cooperating with you.

Bandung